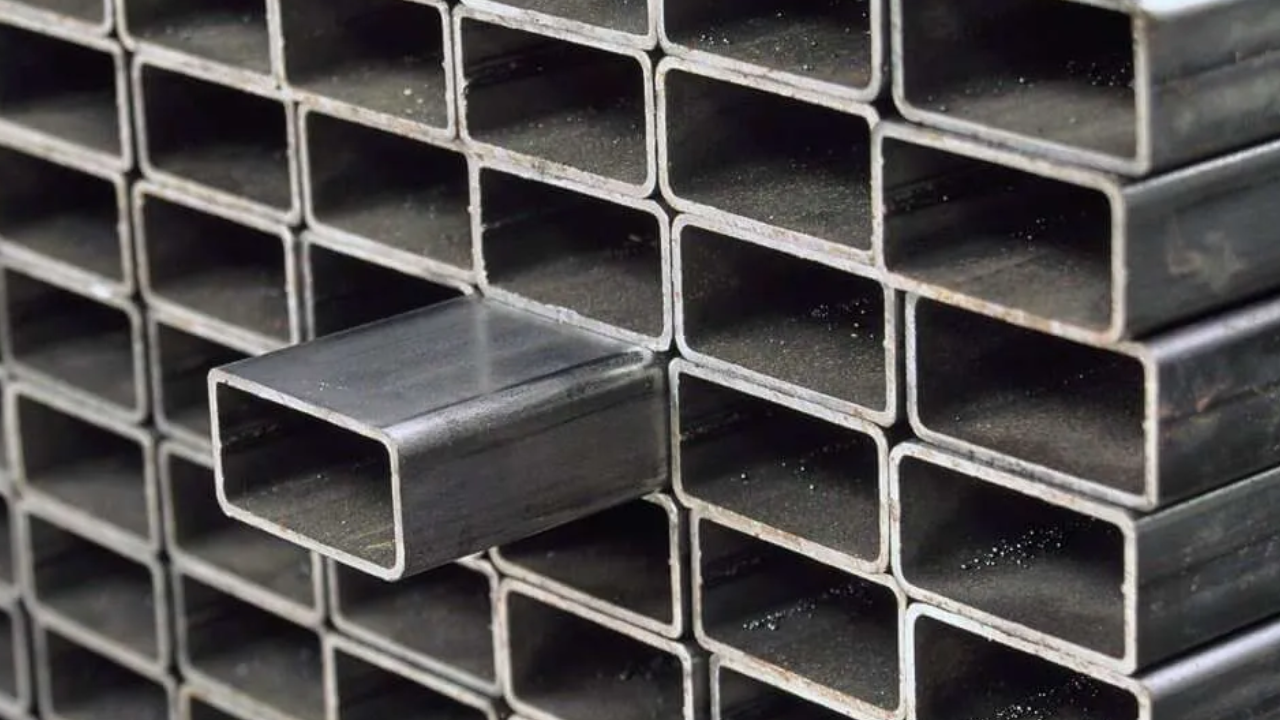

Rectangular hollow section (RHS) stands proud as a flexible and value-powerful structural component, prized for its flat surfaces and extensive-ranging programs throughout various industries. Its intrinsic flatness not only simplifies production tactics but also facilitates seamless joining, making it a cheap choice for a multitude of tasks.

It is normally made of metal, even though other substances inclusive of aluminum and chrome steel may also be used. RHS is prominent using its uniformity in dimensions and smooth, flat surfaces, making it a perfect preference for an extensive variety of structural applications.

One of the key advantages of RHS is its intrinsically flat surfaces, which contribute to its cost-efficiency and ease of manufacturing. The flatness of rhs section gets rid of the want for added machining or processing to acquire smooth surfaces, decreasing production time and fees. This makes RHS an attractive alternative for manufacturers seeking to streamline their manufacturing procedures at the same time as keeping superb standards.

Wide Range of Packages

RHS reveals large use across diverse industries because of its versatility and structural properties. A number of the important thing sectors and packages in which RHS is commonly hired encompass:

Equipment Manufacturing

RHS is broadly utilized in machinery production for fabricating structural components and frames and helps due to its energy, durability, and simplicity of fabrication. It provides structural stability and helps equipment and systems, making sure of reliable overall performance in disturbing business environments.

Construction Industry

Inside the production industry, RHS is utilized for a wide variety of structural packages, such as building frames, columns, beams, and trusses. Its flat surfaces and uniform dimensions make it nicely suited for building strong and strong structures, including residential homes, commercial complexes, bridges, and infrastructure tasks.

Metallurgical Industry

Within the metallurgical industry, RHS is hired for diverse applications, consisting of material dealing with, garage racks, conveyor structures, and device help. Its strength and rigidity make it suitable for withstanding heavy hundreds and cruel operating situations generally encountered in metallurgical facilities.

Agricultural Vehicles and Greenhouses

RHS is applied inside the agricultural area for manufacturing car frames, trailers, and agricultural machinery additives. Moreover, it's far hired within the production of agricultural greenhouses and systems, presenting structural aid and sturdiness for crop cultivation and protection.

Car Industry

Within the automobile industry, RHS is applied for fabricating car frames, chassis components, roll cages, and structural reinforcements. Its excessive electricity-to-weight ratio and dimensional balance make it an ideal desire for reinforcing the structural integrity and safety of car motors.

Railway and Toll Road Guardrail

RHS is applied within the production of railway tracks, bridges, and toll road guardrails, supplying support and containment for railroads and roadways. Its durability and resistance to corrosion make it suitable for outside programs to uncover environmental factors.

Box Skeleton

RHS is hired in the fabrication of container skeletons used for the delivery and transportation of products. Its structural integrity and load-bearing capability the safe and comfortable handling of shipments throughout transit, contributing to the performance of logistics and supply chain operations.

Furniture and Ornament

RHS is used in the furnishings industry for manufacturing frames, legs, and structural components of numerous fixture pieces, along with tables, chairs, cabinets, and cabinets. Its easy traces and contemporary aesthetic make it a popular desire for cutting-edge furniture design.

Metallic Systems

RHS is a critical building block within the creation of metal systems, such as warehouses, business centers, sports arenas, and exhibition halls. Its versatility, electricity, and reliability make it critical for growing durable and resilient structures capable of withstanding dynamic loads and environmental factors.

Ending

Rectangular hollow section (RHS) stands as a cornerstone of present-day engineering and creation, presenting an aggregate of strength, versatility, and cost-efficiency. Its intrinsically flat surfaces and uniform dimensions make it a perfect preference for a wide variety of structural packages throughout industries.